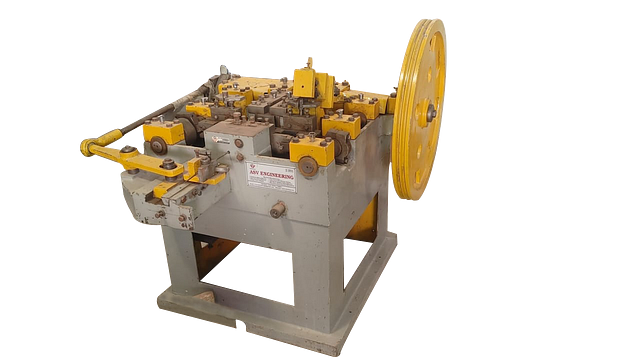

wire nail making machine

wire nail making machineASVR Machine is a dynamic and technology manufacturing company dedicated to wire nail making machine. Established in 2008, we have rapidly grown to become a recognizing in manufacturing & supplying of wire nail making machine. The manufacturing of iron nails typically involves a process that combines various machinery and equipment. Here’s a script overview of the steps involved in making iron nails using a machine:

1. Wire Drawing Machine:

The process usually begins with a wire drawing machine. This machine pulls iron wire through a series of dies to reduce its diameter to the size for wire nail making.

2. Wire Straightening and Cutting Machine:

After drawing the wire, it often goes through a straightening and cutting machine. This machine straightens the wire and cuts it into individual lengths, each corresponding to the length of the nail to be produced.

3. Heading Machine:

The straightened and cut wire is then fed into a heading machine. This machine shapes one end of the wire into the head of the nail. The head can have various shapes depending on the type of Nails being produced.

4. Pointing Machine:

The next step involves a pointing machine. This machine sharpens the other end of the Nail to create a pointed tip. The pointed tip is crucial for easy penetration into surfaces.

5. Thread Rolling Machine:

If the wire nails are designed to have threaded sections, a thread rolling machine may be used at this stage to add threads to the shaft of the nail.

6. Polishing and Coating:

some wire nail go through a polishing process to improve their appearance. Additionally, a coating, such as galvanization or another type of finish, may be applied for corrosion resistance.

7. Quality Control:

Throughout the manufacturing process, quality control measures are implemented to ensure that the Nail meet the required standards. This may involve checking dimensions, inspecting for defects, and performing other quality assurance procedures.

8. Packaging:

Finally, the nails are packaged for distribution and sale.

It’s Important to note that specific details of the process may vary depending on the type of nails being produced and the capabilities of the manufacturing equipment. Additionally, some smaller-scale or specialized operations may combine multiple steps into a single machine.

automatic wire nail making machine

automatic wire nail making machineBenifits of Wire Nail Making Machine:

Investing in a wire nail making machine can offer several benefits for companies involved in nail manufacturing. Here are some of the key advantages:

- Increased Production Efficiency:

Wire nails making machines automate various stages of the nail manufacturing process, leading to increased production efficiency. These machines can produce a large number of nails in a relatively short period, helping companies meet demand and fulfill orders promptly. - Consistent Quality:

Automation through a wire nails making machine ensures a high level of consistency in the size, shape, and quality of the produced nails. This can lead to improved product quality and customer satisfaction.

3. Cost Savings:

Automated machines can significantly reduce labor costs by performing tasks that would otherwise require manual labor. The overall cost of production per unit decreases, contributing to improved profit margins.

4. Customization and Flexibility:

Many wire nails making machines allow for easy adjustment of parameters, facilitating the production of different nail sizes and types. This flexibility enables companies to respond quickly to market demands and diversify their product offerings.

Before investing in a fully automatic wire nail making machine, it’s crucial for companies to assess their specific production needs, available space, and budget constraints to select the most suitable machine for their requirements.

Contact Us:

Phone no:- +91–7050008080

G-mail:- [email protected]

Visit Our Site:- www.asvrmachine.com